We improved Ti DLP technology by reducing Ti DLP ® Pico ™ The size of the chipset makes it suitable for smaller applications. As a result, engineers can develop small high-quality 3D printers that can be used and affordable by more people.

Mattia Mercante is not a master sculptor, but her solution can repair the famous work "the panel of Cosimo III" (wood carving in the 17th century) by sculptor Grinling gibbon without further damage to the exquisite patterns.

As a free repairman, Mattia mainly works for Fondazione opificio, an Italian heritage conservation institution. He set a precedent for using 3D printing technology to make high-precision replacement parts for damaged historical relics.

"Under similar circumstances, the significance of 3D printing is not limited to helping prototype production," he said. "It can make possible goals that could not have been achieved before.".

Mattia's work is inseparable from the increasingly popular photopolymerization 3D printing technology. Unlike the plastic wire used in most mainstream 3d printers, photopolymerization uses precisely controlled ultraviolet light to harden the photosensitive resin into the desired shape. Due to the higher resolution, the accuracy of the final printed product can reach the micron level.

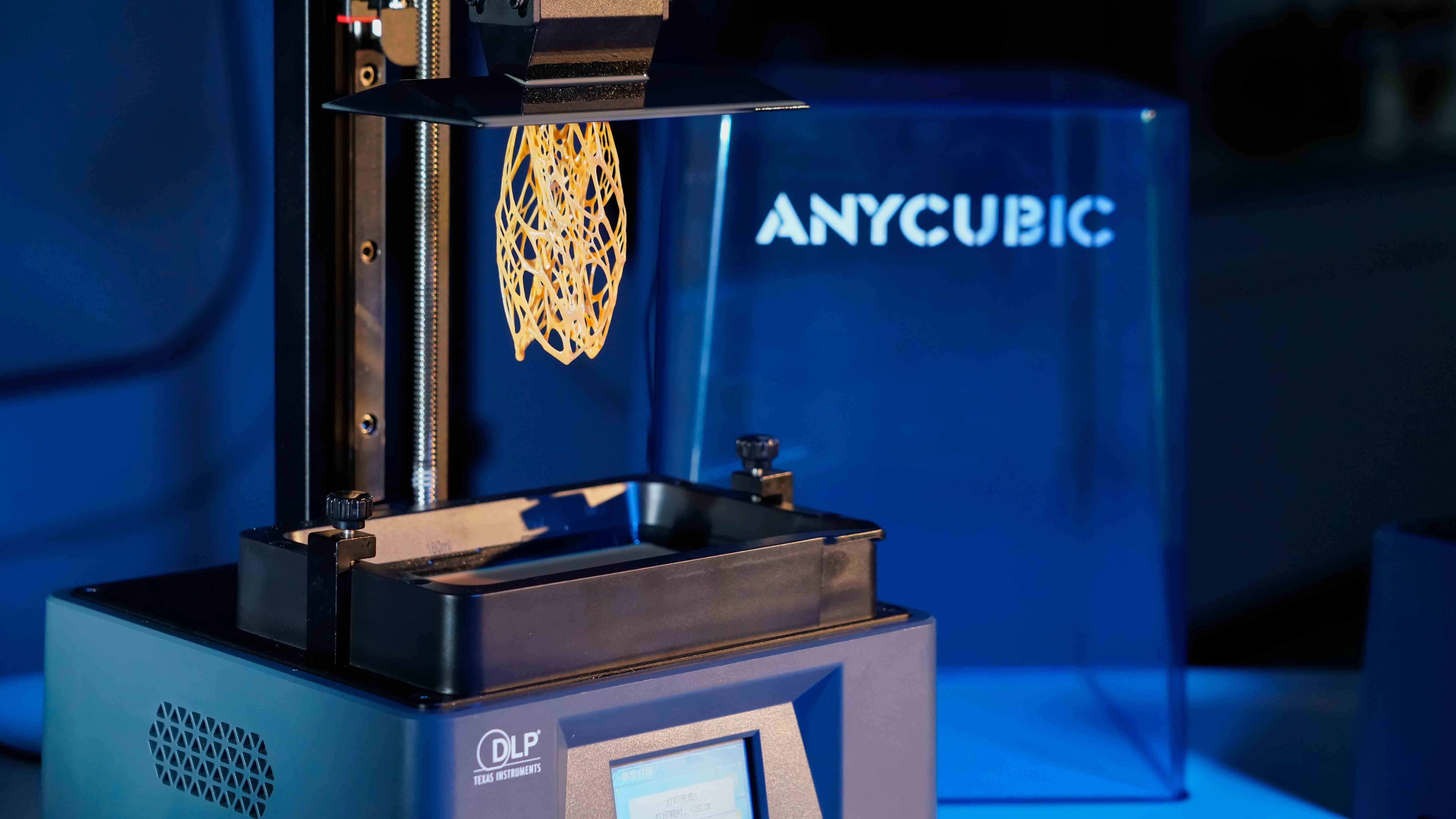

Anycupic, located in Shenzhen, China, is one of the first companies to develop economical 3D printers using Ti DLP Pico chipsets.

Some photopolymerization printers use mobile laser to cure resin point by point, while Ti DLP technology performs 3D printing through high-power full-layer exposure, so as to reduce printing times and improve manufacturing accuracy. Ti DLP technology uses an array composed of millions of individually controlled micro mirrors (also known as "digital micro mirror device" (DMD)), which projects a pattern onto the resin in a 3D printer to print the whole layer at one time.

However, the high cost has become a challenge, which not only limits the use of high-quality 3D printers for large-scale manufacturing, but also shuts out personal studios such as Mattia. However, the new Ti DLP Pico chipset is smaller than the previous version, which makes the high-quality 3D printer have the ideal size and can be placed on the desktop at home or in the office. In addition, it sells for less than $499. Less than half the price of the previous DLP 3D printer. Anycupic, based in Shenzhen, China, was one of the first companies to use the technology in 3D printers, reducing the cost of such printers for artists like Mattia.

Mattia said, "I really want to be able to cure large pieces of resin at one time, so I really want to put a 3D printer with Ti DLP technology on my desk.".

Realize independent production

Patrick Vanderpool is an industrial designer. He tried his best to find an engagement ring that can meet his girlfriend's specific requirements. Finally, he decided to design it himself and use 3D printing technology to print and cast the ring. He intends to propose to his fiancee with the ring model, so she needs to provide specific data for the final design.

Patrick Vanderpool hopes to invest in professional 3D printers to run a small jewelry business

Patrick is currently engaged in self owned jewelry design business and needs to show the design concept to jewelry. The fuse manufacturing printer on his desk can not provide enough accuracy for most jewelry models. Therefore, he still relies on the company providing DLP 3D printing service to help him create the final model. Customers need to wait for several days to see the presentation of their design ideas.

With the decline of technology cost, he hopes to buy his own professional 3D printer, so that he can create high-quality models independently faster and at a lower cost.

"It's wonderful to turn the ideas in my mind into objects in my hands," he said. "I want my customers to participate in the development process, and they will feel the same.".

From film to manufacturing

Before DMD was used to project patterns onto photosensitive resins, people used it to project digital pictures on cinemas with DLP ® Chip on the movie screen. The technology was first used in 1999 to project George Lucas's Film Star Wars I: the phantom threat onto the screen.

DLP technology is used in hundreds of electronic products and display products.

Today, with the continuous development of DLP technology, it has been applicable to hundreds of consumer electronic products, display products, automotive lighting and advanced light control applications, including high-resolution automotive headlamps, head up display (HUD), 3D machine vision, augmented reality glasses and high-quality 3D printing.

"With the streamlining of high-end Cinema Technology to handheld projectors, we can also use DLP technology in industrial 3D printing to achieve smaller printers," said Trevor Dowd, TI's product marketing engineer. "In this way, 3D printers can be placed on your desktop while still providing high performance, fast printing and excellent reliability.".

This technology was originally used to show the fierce lightsaber duel scene in the film Ghost threat in the cinema. Now it is used to make 3D printed engagement rings and repair priceless wood carvings, which shows that the technology and its uses have opened up new innovative fields and markets by keeping pace with the times.

"We have witnessed the exciting development of the 3D printing industry. During the epidemic, people used this technology to quickly print mask and ventilator parts, filling another market gap," Trevor said. "As more and more people can use this printer, they will produce new uses every day."

We are keen to make the world a better place

In 1987, Ti invented DMD chip, which once innovated the method of film distribution and projection; After that, it changed the projection technology; Today, it reduces the cost of 3D printing and makes it available to more people. This is just one of the cases where ti innovators are committed to reducing the cost of electronic products and making the world a better place through semiconductor technology. Each generation of innovation is based on the previous generation of innovation, making the technology smaller, more efficient, more reliable and more affordable, so as to open up new markets and realize the wide application of semiconductors in the field of electronic products. At Ti, this is the progress of engineering. This is what we have been doing for decades and now.