As electronic products become smaller and more components are integrated, packaging design to protect integrated circuits becomes more and more important.

With our unique R & D expertise in packaging, product design, technology development and manufacturing, our customers can realize product differentiation through smaller and more integrated chips, so as to improve reliability, enhance performance and make electronic products more economical.

In various applications from medical electronic products to factory automation, the innovation of semiconductor packaging, an increasingly important technology, helps to produce smaller, faster and more reliable chips, so as to improve performance, achieve higher efficiency and lower cost.

"Packaging is a bridge between electronic circuits and the real world," introduced anindya Poddar, R & D director of the company's packaging group. "Whether you're watching a flat screen TV, listening to music with smart earplugs, enjoying the efficiency of machines in an automated factory, or operating an autonomous vehicle, all this is achieved through encapsulated miniaturization and integration."

Semiconductor packages integrate many digital circuits together and connect them to circuit boards to interact with other system components. There are thousands of packaging types.

Electronic products are everywhere, and mechanical systems are increasingly replaced by electronic products.

"Each type of electronic device has different needs," said sreenivasan koduri, a Ti employee engaged in packaging technology. "The requirements for using chips in outer space are different from factory robots, data center servers, mobile phones, dishwashers or electric vehicles. One chip size is not suitable for all use scenarios."

Designing, developing and manufacturing different types of packages requires a series of unique functions in terms of innovation.

Our internal R & D expertise in packaging, product design, technology development and manufacturing provides unique advantages for optimizing packaging technology.

Miniaturization

Before Jack Kilby invented the integrated circuit in 1958, electronic products were encapsulated in glass or metal tubes because these materials could withstand the high heat generated by the circuit. In the decades after Jack made a breakthrough, semiconductors became ubiquitous because each generation of semiconductor devices became more affordable and widely used in the field of electronic products. However, because people paid attention to the function of circuits at that time, people began to use plastics to package integrated circuits.

Now things have changed. Packaging can bring many benefits, so differential circuits as semiconductors become increasingly important. In the initial design stage, it is necessary to decide which package to use to ensure that the device meets the size, power density, performance and reliability requirements of the design engineer.

Today, designers are looking for smaller packages that can handle higher power while still protecting their precision circuits. Some ultra small integrated circuits in the industry are helping engineers create smaller and smaller designs, such as micro wearable electronic devices for patient monitoring applications, micro microphones for voice systems, and micro earplugs supported by ultra small temperature sensors.

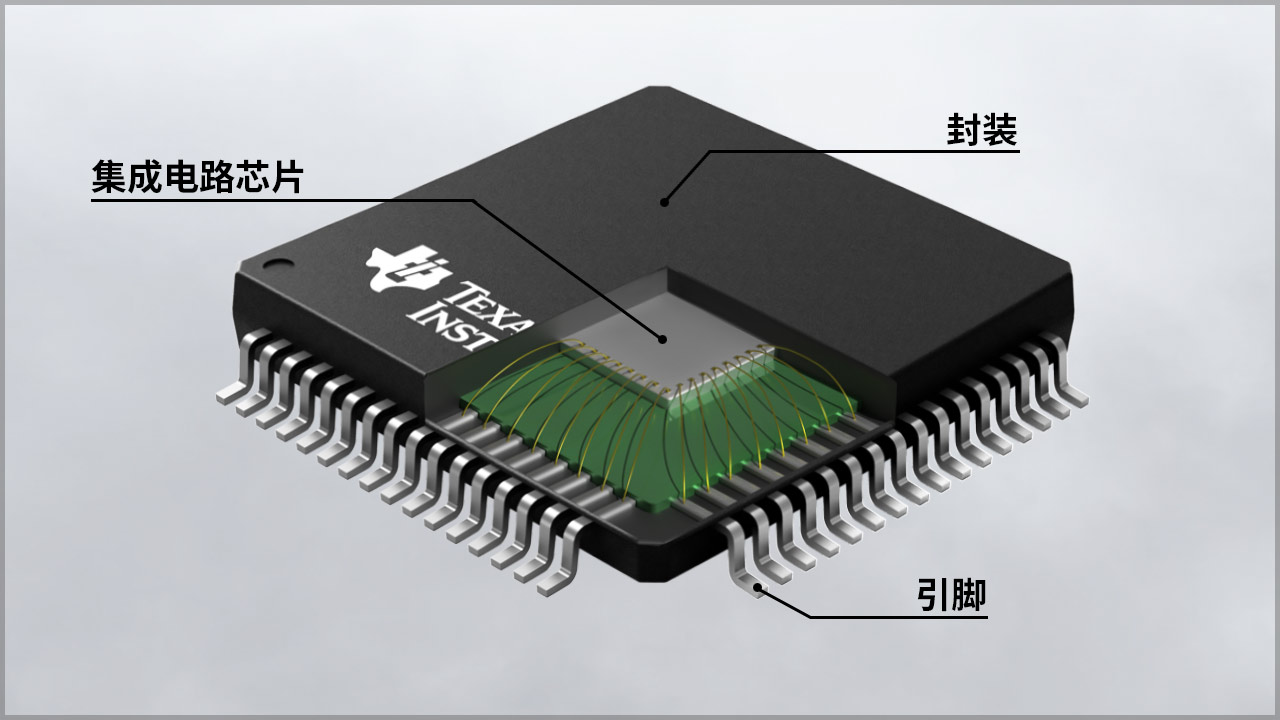

A typical package includes an integrated circuit chip and wires connecting it to pins, which connect the package to a printed circuit board.

Today, we provide industry subminiature operational amplifiers less than one square millimeter, as well as subminiature digital temperature sensors, Ethernet PHY transceivers and isolated can transceivers. Our packaging innovation can realize integrated circuits smaller than a grain of pepper. Our micro products enable designers to reduce the size of the overall solution (and usually reduce costs) or provide more functions in the same space without sacrificing performance and reliability.

"The challenge of miniaturization is how to increase power density in a smaller space," anindya said. "Packaging is essential to meet higher thermal performance requirements so that our customers' products can be safely and reliably reused in a variety of electronic products."

integrate

Packaging multiple chips, inductors, capacitors, barriers and sensors in a single package can reduce the overall component size, reduce the system cost, improve the circuit speed and efficiency and improve the system reliability.

"Integrating these devices allows designers to realize more functions that cannot be realized in single circuit packaging," sreenivasan said. "Integration through packaging opens a new world."

For example, in the automotive market, the industry's advanced gallium nitride (GAN) devices that supply power to the on-board charging system of electric vehicles and meet automotive standards integrate silicon-based Gan field effect transistors (FETs) and silicon gate drivers that can be quickly switched, enabling customers to easily integrate switches, controllers and protection technologies into a single chip in a thermally enhanced package, This enables the solution to withstand higher voltages. Our silicon-based Gan substrates provide cost advantages over similar substrate materials such as silicon carbide by using processing capacity.

In order to help design engineers support more and more power domains in industrial communication applications, our four channel Digital Isolator integrates chip level transformer to realize signal and power isolation in a single small package. Compared with discrete signal and power isolation solutions, in addition to reducing the layout space by 30%, this level of integration also improves the system performance and simplifies the system certification through low radiation in the industry, which is very important for applications in harsh industrial environments.

Our new millimeter wave technology integrates the antenna directly into the package, which reduces the development cost, realizes ultra-small size, and can flexibly place the sensor in more positions (such as door handle). Our millimeter wave innovation provides on-chip system radar technology, which can realize 3D object detection around the vehicle, occupant detection in the vehicle, and bring safety functions to various vehicles.

Improved specifications

With the increasing importance of chip packaging, the boundary between chip design and packaging design no longer exists. Once these were two completely different processes.

"Packaging used to be a passive device to implement circuits, but its role has changed over time," sreenivasan said. "Now, in many cases, packaging is not only supporting, packaging and protecting grains, but also functional. Packaging is improving the specifications of devices."

Micro integrated packaging will continue to improve our way of life, learning and working.

"Encapsulation puts more functions into smaller space and provides more value to users using our products," anindya said. "Integration and miniaturization, together with manufacturing excellence, create innovation opportunities while making electronics more affordable for everyone."

We are keen to make the world a better place

Helping customers design and produce smaller, faster and more reliable products to achieve high performance, higher efficiency and lower cost is a clear proof that Ti innovators are committed to reducing the cost of electronic products and making the world a better place through semiconductor technology. Each generation of innovation is based on the previous generation of innovation, which makes the technology smaller, more efficient, more reliable and more affordable. Opening up new markets can realize the wide application of semiconductors in the field of electronic products. At Ti, this is the progress of engineering. This is what we have been doing for decades and now.