The development of battery technology has spawned a new generation of personal electronic products. Thanks to the progress of technology, products with strict power requirements such as electric tools, electric bicycles and electric vehicles have also developed greatly. Today, with large-scale use, batteries must be safer, more efficient, and more intelligent than ever before. With the increasing functional requirements of intelligent battery pack system, the selection of appropriate MCU becomes more and more important. In this article, we will conduct an in-depth discussion on the ecosystem of msp430tm to help readers understand how to use these functions to solve the challenges in the battery pack system.

Battery pack overview

For basic lithium battery protection requirements, battery protection IC such as bq77915 can be used to ensure that the battery works at its rated temperature and rated current. Some designs need more real-time status information of the battery system to achieve more accurate monitoring and control, which can use battery monitoring IC such as bq76952.

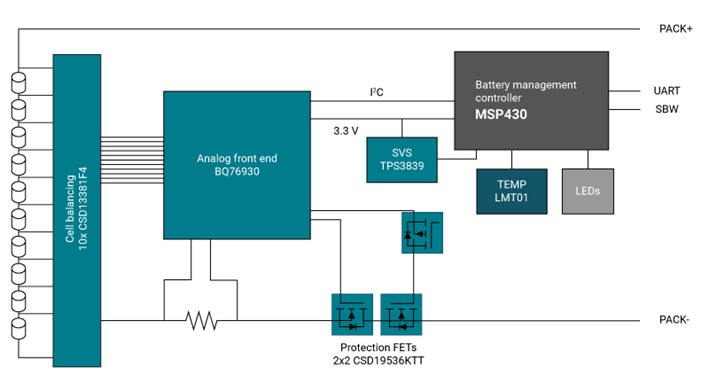

Generally, the high-end battery management IC will be equipped with a microcontroller (MCU) for battery management IC configuration, communication, data processing and calculation, as shown in Figure 1.

Figure 1: block diagram of lithium ion battery pack

In addition, when the system needs more advanced functions such as power tracking or data recording, MCU will play a more important role in the system.

Reduce BOM through low cost sensing

For some battery pack schemes, MCU may be used to detect environmental information (such as temperature). The intelligent simulation combination (SAC) on msp430fr235x can provide great help to this kind of scheme. Sac can replace operational amplifiers and other analog signal conditioning components to reduce the bill of materials (BOM). In addition, sac can realize signal adjustment and amplification without the help of external circuit elements, such as resistance and bias signal, reduce PCB space and reduce cost.

In addition, sac is a peripheral that can be configured in real time at run time, so as to realize the dynamic optimization and adjustment of the system. For example, sac has programmable gain mode and can be configured according to different designs without changing any external components such as feedback resistors. This scheme can reduce the number of external components, increase design flexibility and reduce BOM cost.

In the battery pack system, in addition to temperature detection, sac can also be configured as a general-purpose operational amplifier and used with 12 bit ADC to complete the basic measurement of low side current.

Improve reliability with high-performance memory

In high-performance battery applications, algorithms based on long-term data (such as running state tracking and charge state tracking) are often needed. In an uncertain power environment, flash may be difficult to support the requirements of frequent recording and low storage delay, and there is often a risk of data power loss when storing data in RAM. However, MSP430 devices with ferroelectric random access memory (FRAM) can calmly meet such challenges. Fram is a high-performance memory technology, which can act as flash and ram at the same time. It can realize nonvolatile storage with fast, low delay and low power consumption. Moreover, data can be erased by byte, and the number of erasures is nearly infinite. When the battery triggers the overcurrent or thermal protection circuit, the low delay high-speed storage function of FRAM can greatly reduce the possibility of data loss in case of accidental power failure.

Extend battery life through low power performance

Lower standby power consumption means longer running time. MSP430 device provides a variety of sleep modes, which can meet almost any power supply scenario. Taking msp430fr2355 as an example, its standby current is 620na and shutdown current is 42na.

The use of sac also helps to reduce system power consumption. It can be dynamically enabled when needed and powered off when not needed to reduce power consumption. The traditional signal conditioning technology adopts discrete operational amplifier, which will continue to consume power whether it is in effective working state or not.

Ti also provides software analysis tools such as energytrace to observe the dynamic power consumption of the system, which is convenient for customers' debugging and optimization. In addition, the ultra low power consumption (ULP) advisor tool integrated in Code Composer Studio TM software and IAR embedded workbench can help customers optimize power consumption from the perspective of code.

Save development time with ready to use GUI

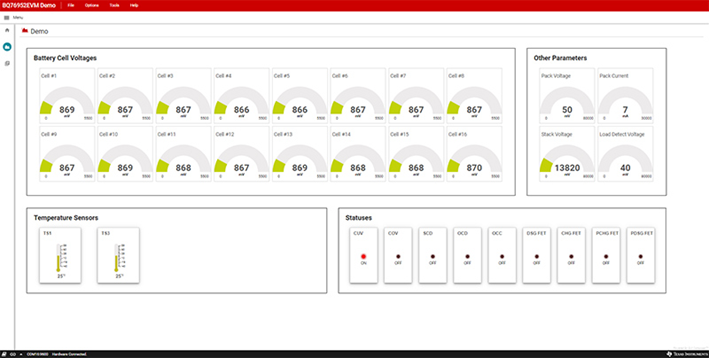

The development of a new system can be a challenging task. The graphical user interface (GUI) provided by MSP430 team can speed up the development and debugging process of bq76952, as shown in Figure 2. By using msp430fr2355 launchpad development kit with bq76952 evaluation module (EVM), you can understand important battery data in detail.

Figure 2: MSP + BQ instrument panel interface

epilogue

With the increasing functional requirements, the battery system will tend to higher energy density, higher security and higher onboard intelligence. The selection of appropriate MCU helps to simplify the product development process and speed up the product launch. The diversified MSP430 MCU product portfolio allows you to easily select the devices that meet your needs in terms of performance, power consumption and cost. See the links below for product information and technical resources.