With the advanced manufacturing process of industry 4.0 sweeping the global market, the demand for highly automated systems is growing rapidly. These systems not only need to run in the integrated manufacturing process, but also need to continuously collect process control data. Most of these systems (including magnetic encoders, proximity sensors, actuators, pressure transmitters, linear motors and autonomous mobile robots in mechanical arms) require advanced position sensing solutions to control performance and collect plant level data, so as to make more informed decisions and improve the safety and reliability of equipment operation.

The autonomous mobile robot shown in Figure 1 can automatically perform simple tasks, such as transporting materials in a warehouse. Such industrial robots can help optimize manufacturing processes, increase production and improve productivity. In order to realize safe and efficient navigation in the factory workshop or warehouse, the wheels of the autonomous mobile robot must have high-precision system control functions such as position sensing and speed control.

Figure 1: autonomous mobile robot traversing the warehouse

Almost all high-performance automation systems that can control motion need position sensing, and the choice of position sensing technology directly affects the cost and performance of the whole system. When evaluating excellent position sensing solutions, factors such as sensor accuracy, speed, power, flexibility and reliability need to be considered.

Multi axis linear Hall effect position sensor can provide highly accurate, fast and reliable absolute position measurement, which is very suitable for precision automation industrial applications. These functions help to achieve more accurate real-time control, which plays a vital role in improving equipment performance, optimizing system efficiency and minimizing downtime.

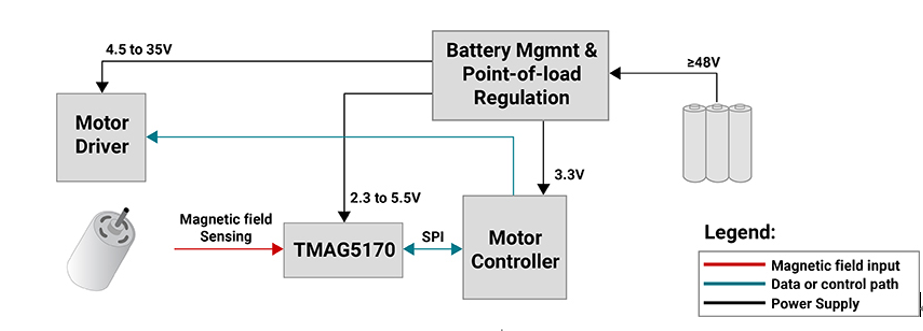

Looking again at the example of an autonomous mobile robot, the block diagram in Figure 2 shows the feedback loop formed between the motor of the wheel and the motor controller. The tmag5170 linear 3D Hall effect position sensor of Ti is used to monitor the exact angular position of the motor shaft and the motor driver, so as to rotate the motor. In addition to all the elements shown in this feedback loop, the linear 3D Hall effect sensor usually has a direct impact on the system bandwidth and delay. By using sensors capable of high bandwidth measurements, you can improve the overall speed of this feedback loop and enhance system performance.

Similarly, the measurement accuracy of the position sensor determines the controllability of the motor movement. The speed and accuracy of the sensor usually fluctuate, so the system performance is limited. Tmag5170 can realize high-throughput data reading, sensing speed up to 20ksps, and high-precision linear measurement. The maximum total error is 2.6%, so you don't have to choose between the two.

Figure 2: block diagram of wheel motor module of autonomous mobile robot using tmag5170 linear 3D Hall effect position sensor

Power consumption may also be an important consideration when selecting position sensors, depending on the designed battery management system or power supply. Battery powered systems or systems using low-power power supplies (e.g., remote 4mA to 20mA loop power supply) usually require sensors with low-power operation modes (e.g., wake-up and sleep and deep sleep modes) to help improve throughput and reduce power consumption. Tmag5170 has multiple operating modes and sampling rates. Compared with other precision linear 3D Hall effect sensors, its power efficiency can be improved by at least 70%, which can reduce power consumption for battery powered devices or light load mode focusing on system efficiency in the sampling range of 1kHz to 20kHz.

In general, position sensors have strict mechanical configuration limitations. Linear 3D Hall effect sensor has rich functions, with optional magnetic sensitivity range and temperature compensation options, which can facilitate your flexible magnetic and mechanical design. Tmag5170 has an on-chip angle calculation engine without off-chip processing, and provides mechanical placement flexibility of sensors and magnets in angle sensing applications, including on-axis and off-axis configurations.

Due to the increasingly close cooperation between industrial systems and labor in automatic operation, more safety measures are needed to ensure operation safety. In addition, the demand for diagnostic functions to prevent tool shutdown and quality problems is also increasing. In addition to accuracy, speed, power and flexibility, reading reliability is also an important factor in the selection of position sensors. For example, if a sensor with a small number or no diagnostic function is selected, a large number of external components may be required to ensure the accuracy and reliability of sensor data, which will increase the bill of materials (BOM) cost of design. Tmag5170 has a unique combination of intelligent diagnostic functions, such as communication, continuity and internal signal path checking, as well as diagnostic functions that can be configured for power supply, input magnetic field and system temperature. The accuracy of sensor data can be ensured without other components, so as to achieve long-term reliability and reduce BOM cost.

High speed and high precision position sensor has realized a new generation of real-time control technology in automatic industrial system. Precision linear 3D Hall effect sensors such as tmag5170 can help designers achieve fast, accurate and reliable measurement without reducing performance or increasing power consumption and cost, thus further promoting the development trend of industrial 4.0 market.